Reduce your operational expenditure, boost your well performance and protect your assets with CobaltAlloy Tubing.

CobaltAlloy™ Tubing was developed to be compatible with Cobalt Sucker Rod Guides to offer a unique well completion package. Includes production tubing, sucker rods, premium rod guides, coupling centralizers and tubing centralizers.

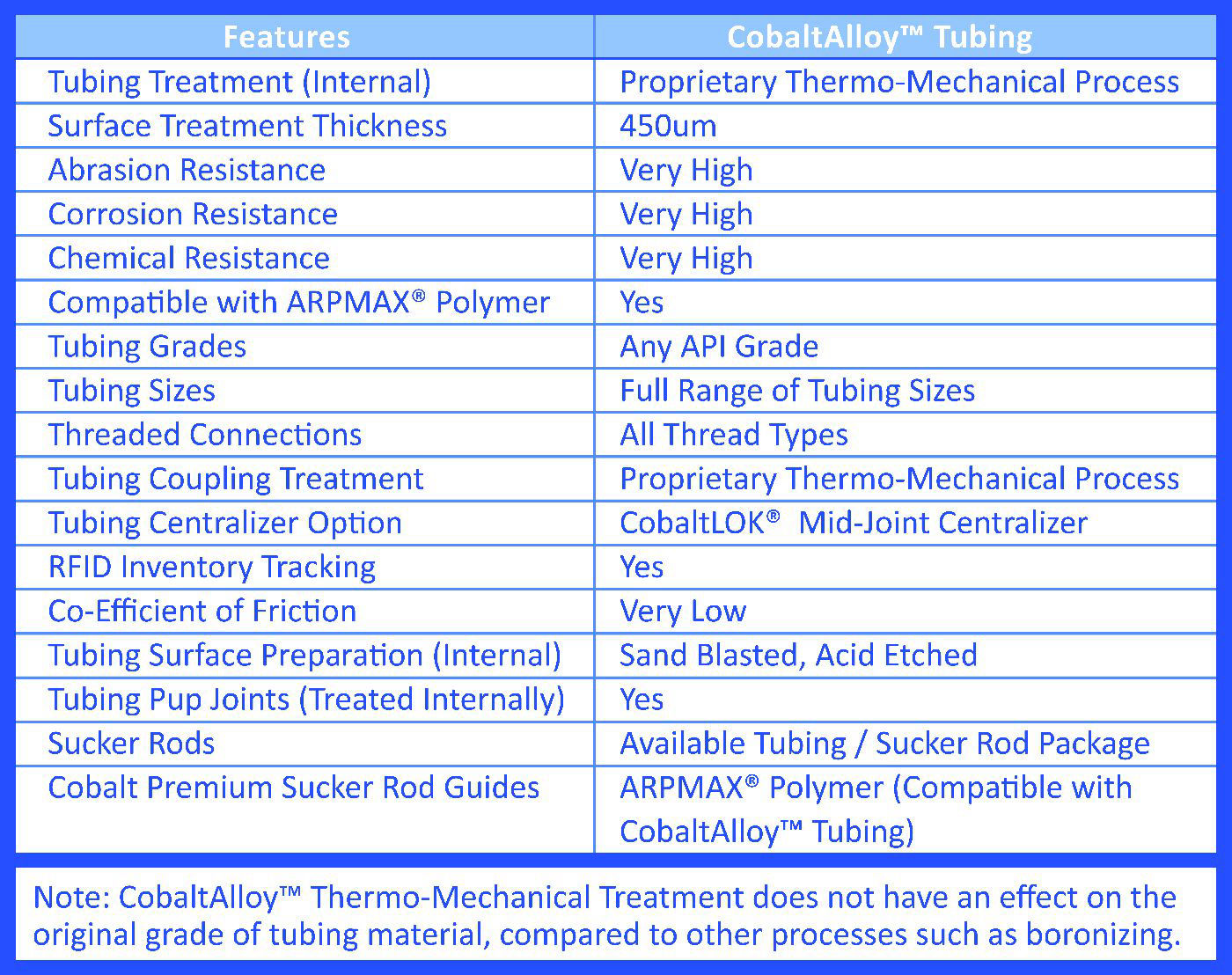

CobaltAlloy™ features reduced friction, lower wear, reduced corrosion, open flow, reduced torque and drag, increased production and reduced well workovers.

• CobaltAlloy™ is available in all API grades, ranges, sizes and tubing thread types.

• CobaltAlloy™ Pup Joints and Couplings are available.